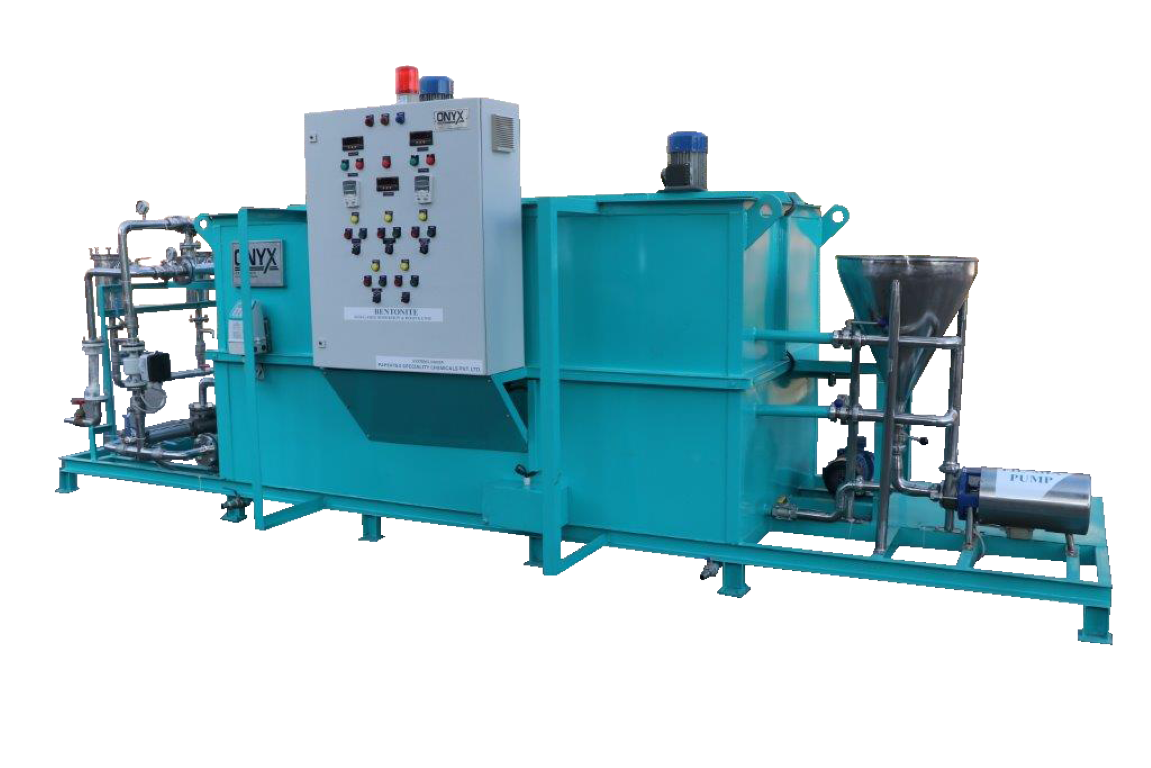

Bentonite is a form of naturally occurring aluminium silicate clay which requires continuous high shear agitation to create gelling effect. Un-dissolved bentonite particles form sediments on the base of the tank.

Our equipment provides high shear and inline mixers which disperses the bentonite granules and creates a uniform solution.

Preparation & Dosing operations are controlled through a single platform enhancing process cycle & single point control.

Preparation & Dosing operations are controlled through a single platform enhancing process cycle & single point control.

KEY FEATURES

- Online concentration of primary solution

- High Shear Mixers

- Effective dispersion of bentonite clay

- Secondary agitator for activated solution

- Preparation & Service Tank level indicator

- Interlinked Dosing Section

- Dosing Pump (Working + Standby)

- Digital Flow Display

- Line pressure indicator

- Filter Assembly

- DCS Compatible

- Alarm for user alert

SAFETY GUARD

- High Tank level alarm

- Low Tank level alarm

- Emergency Shutdown to prevent pump dryrun

- Emergency shutdown against abnormal pipeline back pressure

- Electrical overload alarm